Excello Holdings is dedicated to providing high quality PET bottles to a wide range of consumers. We design and manufacture bottles to ensure that it is tailored as per the client specifications and consistently offer service excellence in all our products.

Excello Holdings is dedicated to providing high quality PET bottles to a wide range of consumers. We design and manufacture bottles to ensure that it is tailored as per the client specifications and consistently offer service excellence in all our products.

Typically, plastic bottles that are used to hold filtered water and other drinks are made out of PET (Polyethylene terephthalate). PET is basically a plastic resin that is the most common type of polyester. Due to its practical properties, such as being a light, safe, strong and transparent material, PET is a popular packaging material and is widely used as a soft drinks container. One key principle has made PET containers a popular option and that is the material’s adherence to quality.

The dynamic industry of plastic bottle manufacturing is advancing in terms of technology to offer a final product that it supreme in its quality finishes and designs. At Excello Holdings, our skilled management and staff works towards exceeding our client expectations and ensuring that all safety and quality control standards are maintained throughout the process of PET bottle manufacturing. We constantly monitor and assess emerging technologies and employ a series of quality checks at every stage of production to guarantee that the PET bottles we deliver are up to the best standards and designs.

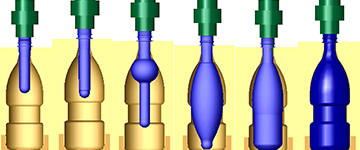

We provide blow molding solutions that are designed to meet the specific requirements of our clients. We execute complex design criteria and employ the highest standards of quality and service to ensure that we deliver innovative production solutions.

We provide blow molding solutions that are designed to meet the specific requirements of our clients. We execute complex design criteria and employ the highest standards of quality and service to ensure that we deliver innovative production solutions. We have been recognized as leaders in injection molding where we design and mold plastic products that gives our clients the competitive edge in terms of overall appeal, quality, efficiency and enhanced profitability. Our injection production method ensures high quality products and a streamlined manufacturing process.

We have been recognized as leaders in injection molding where we design and mold plastic products that gives our clients the competitive edge in terms of overall appeal, quality, efficiency and enhanced profitability. Our injection production method ensures high quality products and a streamlined manufacturing process.